Researchers in China have made a significant breakthrough in solid-state lithium battery technology that could dramatically reshape the future of flexible electronic devices. A team from the Institute of Metal Research at the Chinese Academy of Sciences has developed a new type of flexible solid-state lithium battery capable of withstanding 20,000 bending cycles without performance degradation. Their findings, recently published in the prestigious international journal Advanced Materials, mark a major advancement in addressing some of the most persistent challenges facing solid-state battery development—namely, high interfacial impedance and low ionic transport efficiency.

Solid-state lithium batteries have long been recognized for their high energy density and superior safety compared to traditional liquid-electrolyte lithium-ion batteries. However, widespread adoption has been hindered by poor solid-solid interface contact between the battery’s electrodes and electrolytes. This results in high resistance to ion flow and reduced electrochemical efficiency, ultimately limiting their practical usability, especially in flexible or wearable electronics.

To overcome this barrier, the Chinese research team leveraged the molecular design flexibility of polymers to create an innovative solid-state electrolyte material. By integrating ion-conducting ethoxy groups and electrochemically active short sulfur chains into the polymer’s main chain, they achieved seamless molecular-level interfacial contact between the electrolyte and electrodes. This design not only enhances ionic conductivity but also enables the material to switch between ion transport and storage functions depending on the operating voltage, a feature that introduces a new level of control and adaptability in battery behavior.

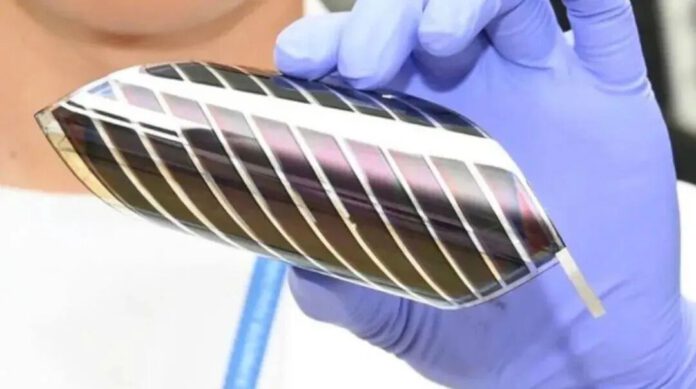

The resulting flexible batteries demonstrated exceptional mechanical resilience, withstanding up to 20,000 cycles of bending without significant degradation in performance. Moreover, when used as the polymer electrolyte in composite cathodes, this new material enabled an increase in energy density of up to 86%. This improvement not only makes these batteries more efficient but also contributes to miniaturization and flexibility in device design, two essential qualities for next-generation electronics.

This development arrives at a pivotal time in the evolution of smart technology. With the rapid proliferation of smart hardware, smartphones, and wearable devices, consumer electronics are becoming thinner, more versatile, and increasingly flexible. Since the emergence of full-screen smartphones in 2017, global tech giants like Samsung and Apple have been actively investing in foldable and bendable devices, signaling a clear industry shift toward flexible form factors. These futuristic, sci-fi-inspired products are no longer just conceptual showpieces at electronics exhibitions; they are increasingly entering the consumer market, shaping the trajectory of the electronics industry.

Flexible electronics have previously been recognized among the world’s top ten technological advancements, and projections suggest that they will revolutionize the design and function of future electronic systems. According to market research firm IDTechEx, the flexible electronics market was valued at US$46.94 billion in 2018 and is expected to soar to US$301 billion by 2028. This represents a compound annual growth rate of nearly 30% from 2011 to 2028, highlighting both the commercial promise and the intense demand for technological innovation in this sector.

Yet, a critical bottleneck in the progress of flexible electronics has been the development of equally flexible and reliable energy storage solutions. Traditional lithium-ion batteries and supercapacitors, designed with rigid structures, are ill-suited for flexible applications. When bent or folded, these conventional batteries risk detachment between electrode materials and current collectors, leading to reduced electrochemical performance, potential internal short circuits, and even safety hazards. Therefore, the emergence of high-performance, bendable energy storage devices has become a focal point in global research efforts.

Against this backdrop, the Chinese research breakthrough represents more than just an incremental improvement in battery chemistry—it could catalyze a new era in energy storage systems. By enabling batteries that are both flexible and efficient, this innovation directly addresses the most critical challenge hindering the practical implementation of flexible electronics. It lays the groundwork for a generation of electronic devices that are not only portable and compact, but also foldable, wearable, and seamlessly integrated into everyday life.

Furthermore, the molecular-level interface design approach introduced by the research team offers a new research paradigm that could influence future material development strategies across multiple domains of battery science. If commercialized, such technology has the potential to accelerate the adoption of flexible smartphones, medical wearables, foldable tablets, smart textiles, and even bendable solar panels. This would significantly expand the design possibilities for engineers and product designers, while improving the energy storage capabilities and safety of mobile and wearable devices.

China’s advancement in flexible solid-state battery technology marks a critical turning point in the race toward next-generation electronics. By resolving the longstanding issue of solid-solid interfacial inefficiency and introducing a high-performance, flexible battery design, this research not only advances battery science but also provides the necessary energy foundation to unlock the full potential of flexible electronics. As market demand intensifies and consumer expectations evolve, innovations like these will likely serve as the bedrock of future technological transformation in both consumer and industrial electronics.

Source: imr cas, Advanced Materials, eet China