The ocean, Earth’s largest natural carbon sink, absorbs over a quarter of anthropogenic carbon dioxide (CO₂) emissions annually, playing a crucial role in mitigating global warming. However, this ongoing absorption has led to a significant and growing problem: ocean acidification. As CO₂ dissolves into seawater, it forms carbonic acid, lowering pH levels and threatening the delicate balance of marine ecosystems, endangering everything from coral reefs to plankton populations. Addressing this dual challenge of climate change and acidification demands innovative, large-scale, and sustainable carbon management technologies.

On October 6, a collaborative research team led by Professor Gao Xiang from the National Key Laboratory of Quantitative Synthetic Biology and the Institute of Synthetic Biology at the Shenzhen Institute of Advanced Technology, Chinese Academy of Sciences, alongside Professor Xia Chuan’s team from the University of Electronic Science and Technology of China, announced a major scientific breakthrough. They have proposed and experimentally validated an artificial oceanic carbon cycle system that integrates electrocatalysis with biocatalysis. The study was published in the high-impact journal Nature Catalysis.

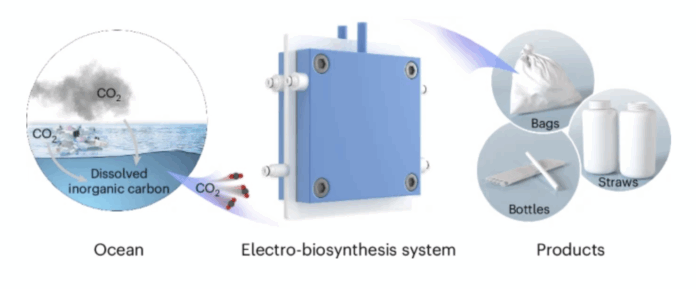

This pioneering system is designed to extract carbon dioxide directly from natural seawater and convert it into valuable intermediates suitable for biomanufacturing. These intermediates can then be transformed into high-value chemicals and sustainable materials. As a proof of concept, the research demonstrates the successful production of biodegradable plastic monomers, laying the foundation for a versatile green manufacturing platform capable of producing fuels, pharmaceuticals, food ingredients, and industrial chemicals.

The first stage of the system, led by Professor Xia Chuan’s team, involves an advanced electrocatalytic process that captures CO₂ from seawater with high efficiency. One of the major technological hurdles in such systems—electrode passivation and salt deposition—was successfully overcome by engineering a novel electrolytic apparatus. The system achieved stable, continuous operation in natural seawater for over 500 hours, with carbon capture efficiencies exceeding 70%. Notably, the system also generates hydrogen as a valuable by-product. Economically, the team estimates the cost of carbon capture at approximately US$229.90 per tonne, a competitive figure in the context of emerging carbon capture technologies.

Further advancing the process, the team developed a high-performance, bismuth-based electrocatalyst (Bi-BEN) that selectively converts captured CO₂ into formic acid—a key intermediary. Their scaled-up electrolyzer operated stably for 20 consecutive days, consistently producing high-concentration, pure formic acid, demonstrating the system’s reliability and scalability.

The second critical phase, led by Professor Gao Xiang’s team, focused on the biological conversion of formic acid into industrially relevant materials. Although formic acid is widely available, its biological toxicity poses a significant challenge for microbial processing. To address this, the researchers engineered a “supercell”—a genetically modified strain of Vibrio natriegens, a fast-growing marine bacterium—capable of thriving in high-formic-acid environments. Using synthetic biology and directed laboratory evolution, the team reprogrammed the organism’s genetic circuitry to efficiently use formic acid as the sole carbon source.

The engineered strain successfully converted formic acid into succinic acid and lactic acid, the monomers for the biodegradable plastics polybutylene succinate (PBS) and polylactic acid (PLA), respectively. These biodegradable plastics are not only environmentally friendly alternatives to petroleum-based plastics, but also demonstrate the feasibility of the system for large-scale production of green materials.

Crucially, PBS and PLA serve only as demonstration products for the broader capabilities of the platform. Thanks to modular design principles and the ability to optimize both the electrocatalytic and metabolic pathways, the system can be tailored to produce a wide variety of bio-based chemicals, including organic acids, plastic monomers, surfactants, and even nutritional ingredients. These products have applications across numerous industries, such as sustainable materials, green chemistry, pharmaceuticals, and food technology.

Looking forward, the research teams plan to establish an integrated “green factory” in coastal areas. These facilities will utilize ocean water directly, capturing CO₂ and converting it continuously into formic acid using the electrocatalytic device, which is then fed into fermentation tanks where engineered microbes manufacture sustainable materials. Such plants could be co-located with existing chemical or manufacturing infrastructure, creating a closed-loop system for carbon utilization and ocean health restoration.

From a strategic and ecological perspective, the significance of this research cannot be overstated. First, it offers a practical solution to ocean acidification, one of the most urgent but often under-addressed consequences of climate change. By actively removing CO₂ from seawater, the system helps restore the ocean’s pH balance, thereby protecting marine biodiversity and fisheries.

Second, the innovation bridges the gap between carbon capture and value-added production. Unlike traditional carbon capture and storage (CCS) methods, which often involve costly long-term storage of captured CO₂ in geological formations, this approach transforms captured carbon into economically viable products. This creates a strong financial incentive for widespread adoption and aligns environmental goals with industrial interests.

Third, the platform promotes the development of a circular carbon economy. Instead of releasing CO₂ into the atmosphere or relying on fossil carbon sources, the system recycles atmospheric carbon—via seawater—into materials essential for daily life, such as plastics, fuels, and nutrients. This model could play a pivotal role in decarbonizing manufacturing sectors while minimizing plastic waste and reducing dependence on petroleum-based feedstocks.

Moreover, the research aligns with China’s broader environmental goals and its ambitions for green innovation under the “dual carbon” targets—carbon peaking by 2030 and carbon neutrality by 2060. The artificial oceanic carbon cycle system, if scaled effectively, could contribute significantly to these goals while strengthening China’s position as a global leader in synthetic biology, clean energy, and green manufacturing.

This groundbreaking research offers a visionary yet scientifically grounded pathway for addressing ocean acidification, mitigating climate change, and building a sustainable bioeconomy. It represents a convergence of advanced electrocatalysis, synthetic biology, and environmental engineering to create a new paradigm: one in which the ocean is not only a passive absorber of carbon but also an active participant in humanity’s transition to a greener, more sustainable future.

Source: Nature, CAS