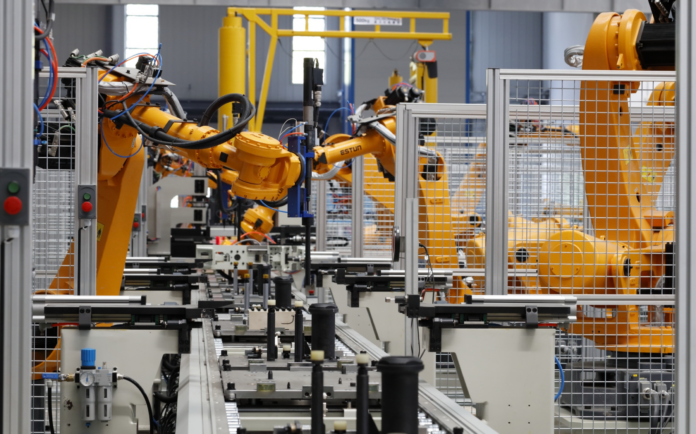

China’s Ministry of Industry and Information Technology reports that from 2013 to 2022, China’s share in the global manufacturing industry surged from 22.5% to 30%, securing its position as the world’s leading manufacturing country for an impressive 13 consecutive years.

Beneath this growth lies a shifting industrial landscape driven by a new wave of technological revolution, particularly in artificial intelligence. Simultaneously, global industrial chain restructuring is being influenced by changes in the international political and economic climate. China’s manufacturing sector now grapples with tightening external demand, the waning demographic dividend, and various other tests.

Establishing and implementing a long-term strategy for the new decade has emerged as a pressing development imperative for Chinese manufacturing.

The importance to overcome the cycle

For companies like Lenovo and TCL, which emerged in the latter half of the previous century, navigating through evolving business landscapes has been both an opportunity and a significant challenge. Entrepreneurs and investors, who have weathered the varying phases of growth acceleration and deceleration, recognize the criticality of fostering long-term endogenous growth for the sustained prosperity of an enterprise.

While it’s crucial for enterprises to make short-term preparations to maintain operational flexibility, a forward-looking perspective spanning over a decade, or even several decades, is equally imperative. Sometimes, it’s not about establishing a rigid path first, but rather, setting a robust goal and then formulating the path accordingly,” suggested Deng Feng, founding managing partner of Northern Light Venture Capital and vice chairman of CEC. In an era marked by monumental shifts, long-termism takes precedence. It involves focusing on the broader trajectory of social development and selecting a wide and enduring course.

Chen Dan, Chairman of Guangdong Evergreen Conglomerate, underscored that the crux of long-termism lies in maintaining stability, excellence, and strength, without necessarily pursuing sheer size. Service and product quality should serve as guiding principles.

Translating the concept of long-termism into tangible action requires the formulation of practical operational measures, development benchmarks, and even the cultivation of a corporate culture.

According to Li Dongsheng, founder and chairman of TCL, amidst uncertainties ranging from sweeping global economic cycles to nuanced industry shifts, companies must be poised to navigate industry cycles at a strategic level. This necessitates the cultivation of capabilities aligned with these cycles.

Chinese manufacturing goes overseas

In its early stages, China’s manufacturing industry primarily engaged in OEM production for overseas markets. However, as operational capabilities improved, Chinese brands began incorporating comprehensive capabilities in R&D, production, and branding into their strategic planning for overseas expansion.

Among the competitive domains within the global manufacturing industry, home appliances emerged as a pivotal track. Globalization, in this context, wasn’t merely a subjective aspiration, but rather an objective necessity. This entailed the establishment of an integrated, synergistic global framework encompassing R&D, manufacturing, and marketing—a framework capable of delivering a comprehensive spectrum of research, development, production, and marketing services on a global scale.

According to many entrepreneurs who participated in this seminar, the successful execution of overseas M&A hinges on cross-cultural integration of operational capabilities and locally tailored strategic adjustments. This strategic approach not only facilitates the smooth integration of overseas acquisitions but also serves as a gateway for Chinese enterprises to embark on their global journey.

Lenovo, a pioneering manufacturing company that has successfully globalized its operations, has adopted a comprehensive internationalization strategy encompassing its business, team, and corporate governance structure. This approach has been instrumental in the company’s sustained success on the global stage.

Over the past decade, overseas mergers, acquisitions, and investments have played a crucial role in broadening the horizons of China’s manufacturing industry. Through the infusion of global technological capabilities and management concepts, these endeavors have catalyzed the domestic industry’s upgrading. In this dual-cycle dynamic of domestic and international mutual promotion, Chinese enterprises have laid the groundwork for a sustained global presence.

Since its pivotal acquisition of IBM in 2004, Lenovo has strategically established branches, R&D centers, and manufacturing facilities in over a hundred countries worldwide. This expansive global footprint has led to overseas revenue constituting more than 70% of the group’s total revenue.

Ning Min, Chairman of Lenovo, emphasizes the critical role played by local teams in empowering various segments of the group. This collaborative approach remains integral to Lenovo’s business model, combining a localized supply chain in China with a globally oriented operational framework. This forward-looking strategy ensures the company’s continued growth and adaptability in a dynamic international landscape.

Build new comparative advantages

Looking back on the evolution of China’s manufacturing sector, it’s evident that globalization and demographic dividends played pivotal roles, shaping the industry’s growth trajectory. Initially, labels like “low price, low quality, and low return” were associated with Chinese enterprises, serving as both a comparative advantage and a starting point for development.

In recent years, however, a shifting geopolitical landscape, a surge in trade protectionism, and mounting challenges in technology access have introduced new complexities to the global competitive arena. Simultaneously, the demographic dividend that once fueled growth is showing signs of waning. As we look toward the next decade, the sustainable success and long-term viability of China’s manufacturing industry will hinge on enterprises identifying fresh areas of advantage.

Manufacturing stands as the industry most profoundly impacted by technological advancements. In this critical era of digital transformation, the integration of next-generation technologies like artificial intelligence into manufacturing R&D and production processes lays a robust foundation for transitioning from “Made in China” to “Innovated in China.”

Chang Zhenming, former chairman of CITIC Group, underscores the importance of building substantial and robust technological reserves for navigating this era of monumental change. This reservoir of technology and products will be the linchpin for future competition and a pivotal determinant of enterprise destiny.

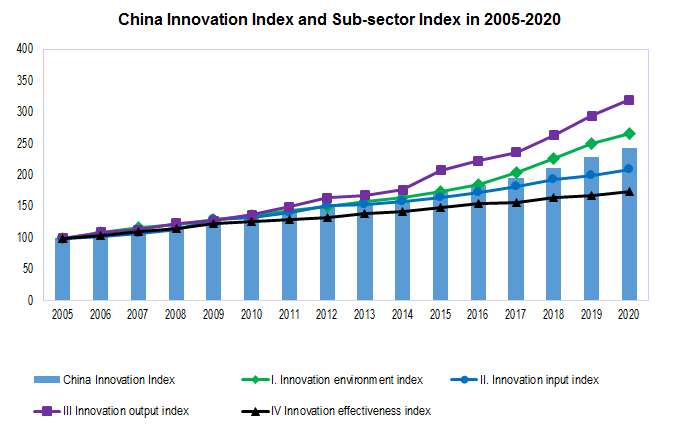

Building a robust technological infrastructure and establishing proprietary advantages require sustained investment from enterprises. According to the China Enterprise Confederation, in 2022, the R&D investment of China’s top 500 manufacturing enterprises surpassed one trillion yuan for the first time.

Deng Feng, founding managing partner of Northern Light Venture Capital and vice chairman of CEC, emphasized that as the demand for independent and controllable supply chain security grows, companies must bolster their R&D and production capabilities. The new wave of technological development presents both challenges and opportunities, with independent innovation offering the chance to reshape and upgrade supply chains.

In the industry context, the significance of software ecosystems across all stages of the industry chain has grown increasingly prominent. Wang Wenjing, chairman and CEO of Yonyou Network, noted that while IT was once the least geographically bound industry, global technology sharing has undergone significant shifts due to external political influences and other factors.

“In the realm of digital interaction and experiential scenarios, products no longer simply offer traditional functionalities. More importantly, they provide a high-quality life experience. This calls for Chinese enterprises to wholeheartedly embrace digitalization and use it as a foundation for continuously propelling industry upgrades and transformations,” highlighted Jia Shaoqian, Chairman of Hisense Group.

(Source: Xinwen Lianbo, McKinsey Greater China, National Bureau of Statistics of China)