Since the advent of rail transit, the pursuit of higher operating speeds has remained a constant human aspiration. Maglev transportation, emerging a century after the development of traditional railways, reshapes the fundamental relationship between train and track by replacing physical contact with electromagnetic interaction. Suspended and propelled solely through magnetic forces, maglev systems overcome the mechanical limitations of wheel–rail friction and open a new frontier of ultra-high-speed ground transportation.

China’s systematic push in this field began in 2016, when the Ministry of Science and Technology launched the Program of Building National Strength in Transportation. Among its priorities was the development of a 600 km/h high-speed maglev system—identified in the national transportation strategy as a core technological reserve alongside 400 km/h wheel–rail trains and low-vacuum tube high-speed systems.

In the decades prior, Germany and Japan had already invested heavily in maglev research, the former focusing on conventional electromagnetic suspension (EMS) using attraction forces and closed-loop controls, and the latter on superconducting electrodynamic suspension (EDS), which relies on the powerful magnetic fields produced by superconductors. China began exploring both maglev and wheel–rail options in the 1990s during planning for the Beijing–Shanghai high-speed railway, laying the foundation for later breakthroughs.

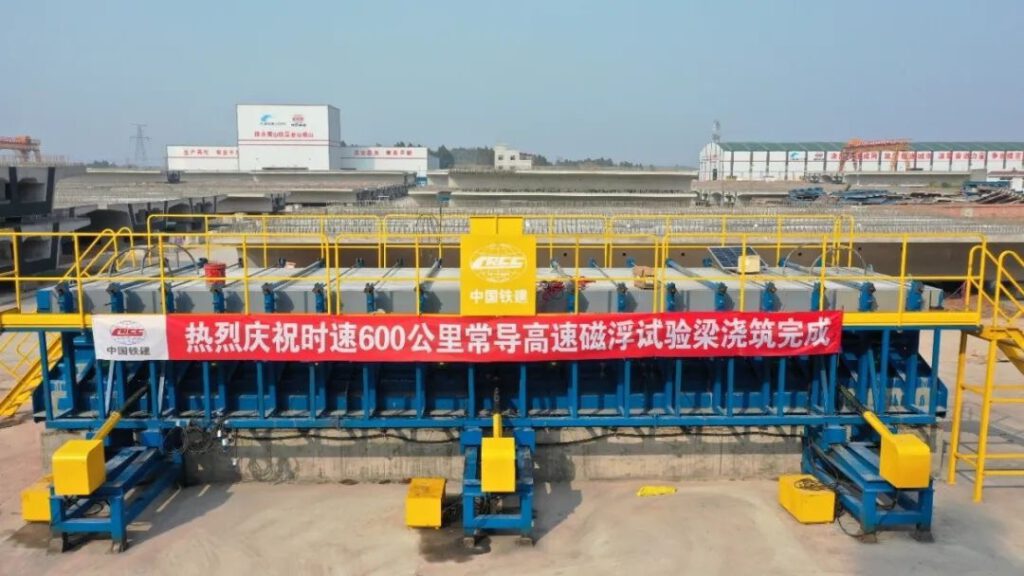

In 2021, China’s first 600 km/h high-speed maglev transportation system was officially released in Qingdao, signaling a major step forward in independent technological capability. On May 27, 2024, China Railway Construction Corporation (CRCC) completed its major research undertaking on the construction technologies for 600 km/h conventional-conductor high-speed maglev systems. This achievement made China the world’s third country to master the complete set of technologies for a 600 km/h maglev system and filled longstanding gaps in independent intellectual property, industrial chain integration, and practical engineering methods. Over four years, the project team carried out research across seven key fields—including bridge engineering, tunnel engineering, and infrastructure-vehicle interaction—resulting in 70 patents, multiple new processes and specifications, several newly developed products, and engineering software that has already been applied in real-world projects.

CRCC’s engagement with maglev research dates back to the 1990s, and its subsidiaries later became deeply involved in the Ministry of Science and Technology’s “Maglev Transportation Systems” program. As one of the principal contributors, the institute helped develop the national “Maglev Railway Technical Standards,” which took effect in 2020. With major urban clusters such as the Guangdong–Hong Kong–Macao Greater Bay Area and the Yangtze River Delta now planning high-speed maglev corridors, the demand for long-distance, high-capacity, ultra-fast ground transportation offers broad prospects for engineering application.

The completion of CRCC’s latest project indicates that China has fundamentally mastered the engineering construction technologies necessary for 600 km/h conventional-guide maglev lines, establishing both a complete system of independent intellectual property and clear design principles for future implementation.

But how fast is 600 km/h? A large commercial aircraft typically cruises at 800 to 1000 km/h, while regional jets operate at around 500 km/h. A 600 km/h maglev runs almost like a “zero-altitude aircraft,” traveling at aviation speeds while remaining grounded. Maglev trains themselves, however, are not limited to high speeds alone. Depending on their suspension technology, materials, and rail structure, they can serve varied transportation needs: high-speed maglev reaching 400–600 km/h, medium-speed systems around 200 km/h, and low-to-medium-speed systems at approximately 100 km/h. The latter are technologically simpler and more economical, suited for urban and suburban transit. China currently operates three such low-to-medium-speed lines: Changsha Maglev Express (2016), Beijing’s S1 line (2017), and the Fenghuang Maglev Sightseeing Express (2022).

The target of 600 km/h is not arbitrary. China’s vast geography requires strong, efficient connections between major regional clusters such as the Yangtze River Delta, the Pearl River Delta, the Beijing–Tianjin–Hebei region, the Middle Yangtze River area, and the Chengdu–Chongqing economic circle. Many core cities—Beijing, Shanghai, Guangzhou—lie over a thousand kilometers apart. High-speed rail takes more than four and a half hours for some of these journeys, while flights are fast but costly and subject to weather and airport logistics. To maximize time efficiency, transportation scholars argue that intercity trips between major metropolitan areas should ideally be completed within about three hours, including intermediate stops. A commercial operating speed of 600 km/h is the practical threshold at which this goal becomes feasible.

At the 17th China International Modern Railway Technology and Equipment Exhibition in July 2025, three major maglev prototypes—conventional high-speed maglev, superconducting high-speed maglev, and conventional medium-low-speed maglev—were unveiled together for the first time. Among them, the superconducting electric high-speed maglev attracted particular attention. Its levitation relies on electromagnetic induction between onboard high-temperature superconducting magnets and coils embedded in the track. These superconducting poles generate magnetic fields exceeding 5 tesla, producing strong, stable forces for levitation and propulsion.

The train integrates cryogenic thermostats, refrigeration units, and advanced thermal management systems to ensure reliable operation of the superconducting components. Lightweight aluminum alloys and carbon-fiber composites form the vehicle body, while an aerodynamically optimized nose reduces drag at high speeds. The system is designed for GoA4 fully autonomous operation, incorporating 5G communication, AI-based monitoring, multilayer redundancy, and comprehensive electromagnetic shielding to balance efficiency, safety, intelligence, and ride comfort. As CRRC senior engineer Shao Nan noted, the independent completion of materials, coils, cryogenic systems, and other core components represents not only a technological milestone but also a catalyst for broader industrial advancement across superconductivity, advanced manufacturing, and high-end rail equipment.

High-speed maglev is an ultra-complex, large-scale systems engineering endeavor that must follow rigorous R&D, validation, and testing procedures before reaching commercial readiness. While China’s conventional high-speed maglev technologies have now reached engineering implementation standards, true commercial operation will require building a dedicated high-speed maglev test line to verify running speeds, operational stability, and long-term safety. Only after these validations can the system officially welcome passengers and open a new chapter in ultra-fast ground transportation.

Source: wuhan gov, xinhua, cjrb, news bjd