“BYD is like a simple, hardworking kid—honest, diligent, and focused on learning,” Wang Chuanfu, chairman and founder of BYD, told investors in December 2025 during the company’s shareholder meeting, once again framing his company through the lens of a practical engineer.

Over the past decade, BYD’s new energy vehicle sales have soared from 58,000 units to 4.6 million in 2025, a growth fueled not by conventional corporate structures or ready-made supply chains, but by a vertically integrated system of self-generated, highly internalized capabilities.

At the heart of this rise is BYD’s engineering workforce. By 2025, the company employed 120,000 R&D engineers, more than most traditional automakers combined, forming what Wang calls a “technical moat.” New graduates are recruited in large numbers and trained under a rigorous mentorship system, transforming students into engineers capable of tackling complex projects. “Managing this scale of employees requires the precision of managing a single individual,” says Ye Zi, general manager of BYD Human Resources.

Wang’s hands-on involvement shapes the company’s culture and technical decisions. Sun Huajun, CTO of BYD’s battery division, recalls Wang in the early years meticulously dismantling faulty batteries with engineers, searching for millimeter-level sealing flaws. Even today, Wang gives in-depth lessons to senior executives on principles ranging from anodic oxidation to grid capacitors, ensuring that technical understanding permeates every level of leadership. Weekly meetings between Wang and division heads review progress, and major strategic choices, like the company’s commitment to lithium iron phosphate batteries or the innovation of the blade battery, emerge from these intensive discussions, blending technical democracy with authoritative decision-making.

This engineer-driven ethos has powered BYD’s meteoric success. From its origins as a battery manufacturer to its leadership in electric vehicles, BYD has redefined cost and efficiency with proprietary technologies like blade batteries and DM-i hybrid systems, building an industrial empire spanning batteries, semiconductors, and energy storage, all rooted in internal technical mastery. Yet by 2025, the rapid electrification was giving way to the slower, more strategic battle over intelligent technologies, where success would hinge not just on battery efficiency or casting methods, but on software, algorithms, data ecosystems, and speed of iteration.

Wang’s philosophy is deeply embedded in the company’s talent development. Early recruits in the 2000s, often high-ranking graduates from China’s top universities, joined BYD because there were few alternatives.

BYD’s “Tomorrow Star” graduate training program, established at the company’s founding in 1998, combines rigorous corporate culture lessons, immersive production-line training, and one-on-one mentorship. Graduates are quickly placed on real projects, often leading initiatives within their first two years. “BYD dares to let fresh graduates take responsibility,” Ye Zi notes. “Some of them become project leaders within a year or two.” This mentorship-project hybrid system ensures the transmission of both knowledge and company values, creating a continuous pipeline of capable engineers.

The company’s internal operating principles, codified in the internal handbook BYD Basic Guidelines, emphasize that decision-makers cannot succeed by sitting in offices alone; they must engage on the front lines, in labs, production floors, and even sales outlets. Wang exemplifies this approach, personally interacting with engineers to finalize technical strategies, while the 120,000-strong R&D workforce translates vision into reality. The blade battery, for example, emerged from Wang’s insistence on achieving 600 km of range with lithium iron phosphate cells, eventually realized by engineering innovations in production tooling and cell arrangement.

Over time, BYD has cultivated a leadership culture distinct from new electric vehicle startups, favoring internal promotion over poaching talent. More than half of the current general managers reporting directly to Wang are alumni of BYD’s own graduate programs. The company has consistently produced top leaders, including heads of research institutes and brand divisions, all forged under Wang’s mentorship. Management scholars like Jim Collins have long noted that visionary companies succeed when leaders are internally developed, a principle BYD has exemplified.

BYD’s explosive growth over the past decade has reshaped its presence in the talent market. The company now recruits thousands of new graduates annually, many from elite universities, most of whom enter R&D roles. Parallel promotion tracks allow technical experts to reach executive-level pay and status without leaving their craft, ensuring talent retention and career clarity. With a structured nine-tier ranking system spanning multiple sub-levels, engineers can navigate a clear, merit-based career path.

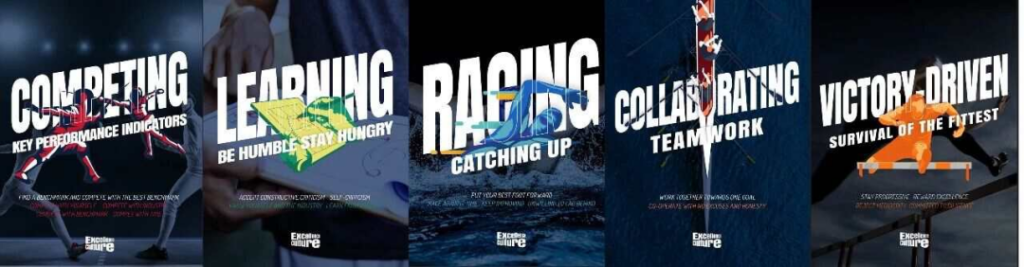

As BYD scaled, its culture of mentorship began to evolve. In 2017, the company introduced a culture of internal competition, later formalized in 2022 as “competing, learning, racing, collaborating, and victory-driven,” emphasizing meritocracy and adaptability. Internal debate is encouraged, but always aimed at outperforming competitors externally. Incentives extend beyond salary, with profit-sharing and equity programs fostering long-term alignment. The system now forms a self-reinforcing loop of selection, development, evaluation, and reward, ensuring that engineers remain aligned with company strategy.

Yet as the industry enters the intelligent mobility era, BYD faces new tensions. Vertical integration, once a source of cost advantage, brings management burdens and potential innovation inertia. Wang has elevated intelligent technologies to a core strategic focus, aggressively recruiting software, algorithms, and human-machine interface talent. By mid-2025, the intelligent driving team exceeded 5,000, including over 1,000 core algorithm engineers. The cultural challenge is integrating highly specialized, digitally native talent into BYD’s disciplined, production-centric engineering culture.

Early signs of synergy are emerging. AI platforms in battery research, for example, enable rapid formulation testing, complementing BYD’s traditional trial-and-error, first-principles approach. Yet the challenge remains: in a large, efficiency-driven organization where internal performance is rigorously assessed, how much room exists for uncertainty and experimentation? In the intelligent era, engineers must not only optimize technology but also understand and create user value.

BYD’s culture of simplicity, “focus on the work, not the person”, remains its guiding principle. It allows the company to command nearly a million employees and a vast industrial chain with the efficiency of a single operator.

Source: BYD, xueqiu, 21jingji, qykc, 36kr, CSDN, xinhua, world journal