After the financial crisis in 2008, the hollowing out of industries in the United States became obvious, coupled with the drawbacks brought about by an over-reliance on finance and real estate, resulting in the general idea of revitalizing the real economy in the United States. The Obama administration launched a re-industrialisation development strategy at the end of 2009, encouraging manufacturing companies to return to the US, to fully revitalize the country’s manufacturing system and ultimately consolidate its economic leadership and global leadership position. After taking office, Trump also maintained the re-industrialization idea and tried to restore the glorious past of the American manufacturing industry, advocating that America should come first. It is natural that Biden wishes to strengthen the strategy.

The US manufacturing: revitalizing rapidly or dying gradually

Biden’s victory for the presidential election was mainly supported by traditional “Rust Belt” states such as Wisconsin, Pennsylvania, and Michigan, and reviving manufacturing was one of his top campaign promises.

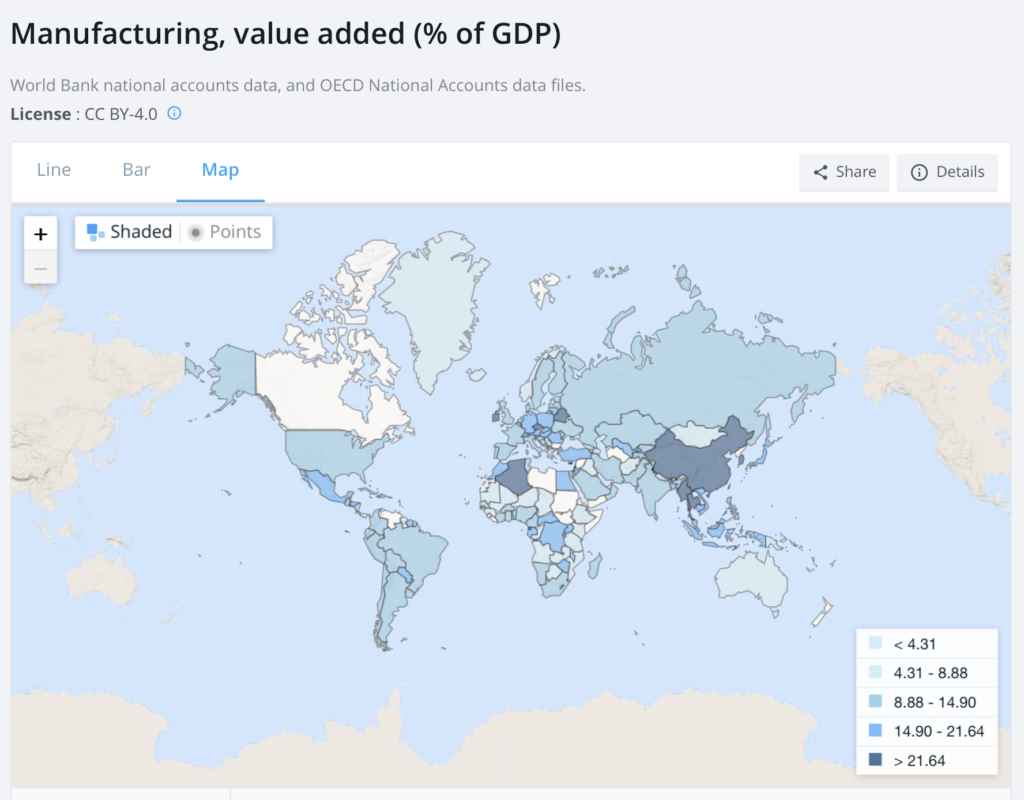

World Bank statistics show that after 2008, US manufacturing outputs of both national GDP and world GDP have steadily declined. According to the U.S. Bureau of Economic Analysis (BEA), the share of manufacturing employment has fallen from 14.6% in 1998 to 8.9% in 2019. In particular, the share of employment in metal manufacturing, chemical industry, and machinery manufacturing, representatives of traditional manufacturing, has fallen from 2%, 0.8%, and 1.3% to 1.3%, 0.6%, and 0.8% respectively. Compared to its glory days in the 1940s and 1950s, the United States is losing its position as a manufacturing powerhouse..

Under the downward trend in traditional US manufacturing is the global industrial shift but the US misunderstands it as that the new employment generated by the growth of innovative industries will compensate for the loss of jobs caused by the out-migration of lagging industries. The decline in manufacturing has led to factory closures and job losses within the US, as well as a steady decline in manufacturing workers’ wages.

The problem with the US traditional manufacturing is more than an economic and industrial one. The US middle class that had been formed on the back of manufacturing has begun to shrink because of unemployment and the downward adjustment of wages and incomes, presenting the seriously widening economic disparities, which is precisely the profound change in American society.

Essentially, the return of manufacturing in the United States is a practical industrial and economic thinking, and the Biden administration must face up to the root causes of its continuing economic contraction and the shrinking middle class. It can be said that reviving manufacturing is a pillar of the Biden administration’s economic and industrial policy, and an important foundation for his administration.

Misunderstanding and mispositioning China in the competition of manufacturing

The Biden administration is facing enormous pressure from the rise of emerging countries represented by China and an international environment in which the reshaping of the world landscape is accelerating, and it must maintain its dominant position in key areas to reflect “America First”. In this process, it is undeniable that the US manufacturing revitalization plan also reflects a misperception of China’s manufacturing and economic development.

The first is a misjudgment of the decline in US manufacturing, which is partly blamed on economic and trade relations with China. In the U.S. view, China’s accession to the WTO in 2001 from the benefits of tariffs has deeply hurt U.S. foreign trade, resulting in huge losses in manufacturing workers’ wages and a decline in U.S. manufacturing.

The second is a misjudgment of China’s economic development, which has been partly attributed to China’s achievement through unfair competitive practices. Successive US administrations did not accurately predict that China’s economic development would be so fast, and when this spectacular performance could continue for a considerable period, US academics and politicians hardly find an answer. One of the explanations is that China has resorted to unscrupulous practices in its foreign trade relations and that Chinese technology has been developed by stealing intellectual property and technology from the world, especially from the United States, which ignores how much China and the Chinese invest and make effort for the national development.

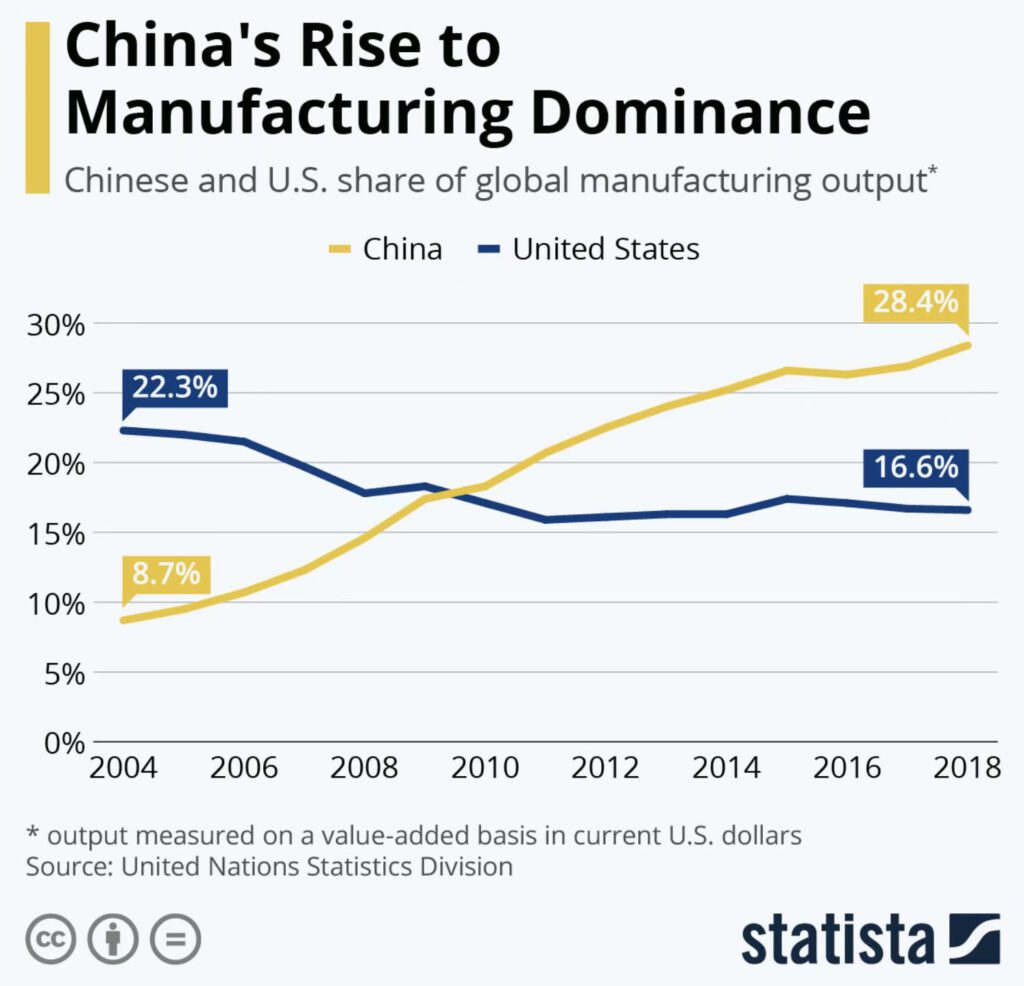

The third is the wrong identification of China only as a competitor in manufacturing and even economic development with the U.S. On August 5, 2021, President Biden’s speech on Strengthening American Leadership on Clean Cars and Trucks noted that China is now leading the electric vehicle sector, being one of the largest and fastest-growing electric vehicle markets in the world and having 80 percent of the production capacity for electric vehicle batteries. China is already the most important competitor to the United States in many areas, including the new energy vehicle industry, and in the 21st-century competition, it is important to ensure that the “future” is made in the United States.

Declining but still leading US manufacturing

The current discussion of the decline of US manufacturing is in fact about traditional manufacturing. The downturn in traditional US manufacturing does not mean that there is an all-encompassing problem in US manufacturing. To this day, the US is still the world leader in the development of high-end manufacturing, especially the advanced manufacturing industry with science and technology innovation at its core, which is the cornerstone of its GDP remaining number one in the world. In contrast, although China has surpassed the United States in overall manufacturing output, it is still in its infancy in high-end manufacturing. It will be difficult for many countries, including China, to surpass the United States’ advantage in advanced manufacturing for a while.

In addition, high cost is frequently discussed in the traditional manufacturing industry in the U.S. In the past decades of the development process, compared to higher labor costs in the U.S., its more stable business environment has already and indeed reduced the overall enterprise manufacturing costs, helping the American manufacturing industry to win a lot of opportunities. According to a new joint study by the Manufacturing Institute (MI) and Klynveld Peat Marwick Goerdeler (KPMG), the US ranks fifth out of 17 major industrial producers in terms of the cost of doing business (including direct and indirect costs of production), just above Canada, China Taiwan, Korea, and Malaysia, and well below even Vietnam, Mexico, Mainland China and others. It can be said that the cost of doing business will certainly be an important factor in the viability of the US manufacturing return plan.

But how much will US manufacturing be revitalized? It is a question that three US presidents hardly answer well – 13 years have passed, except passively imposing different sanctions on others to gain market position for US manufacturing, what else will reviving US manufacturing strategy make difference?

(Source: National Employment Law Project (NELP), World Bank, Statista, ritzherald.com)