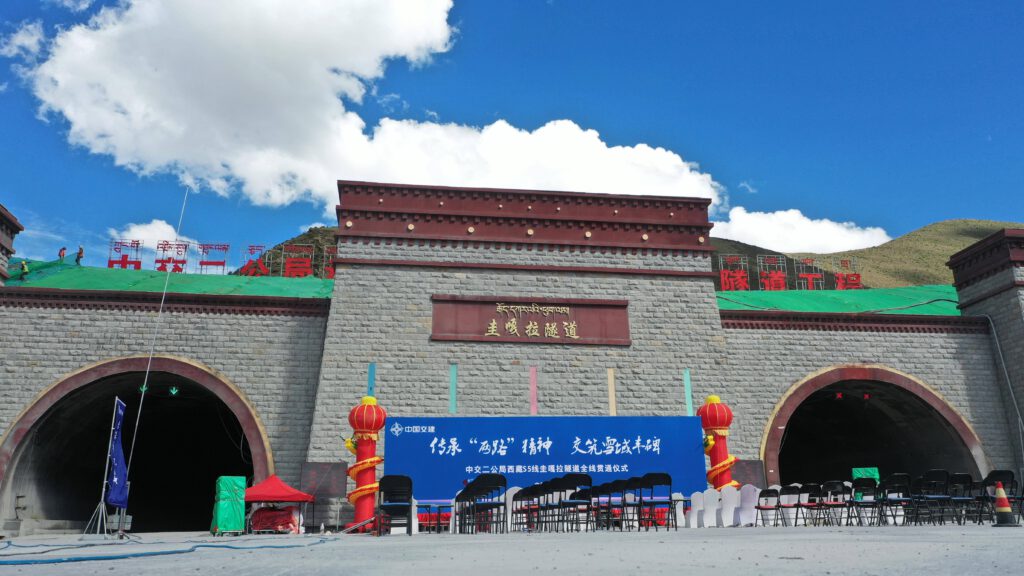

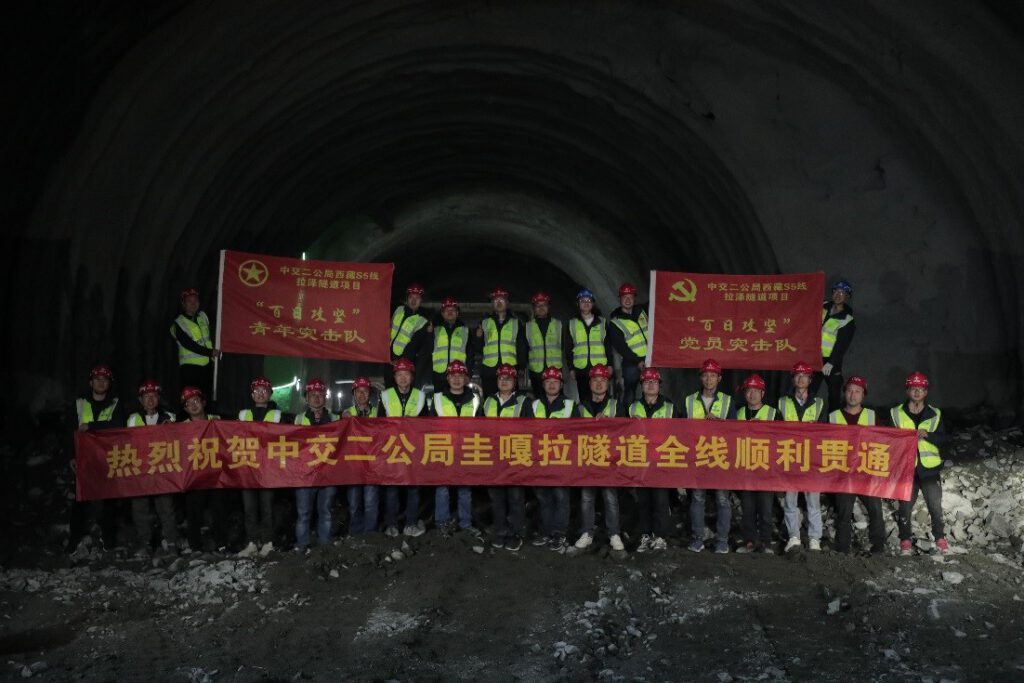

On June 28, the Guigala Tunnel of the Tibet S5 Line Lhasa-Zedang Expressway Project constructed by the China Communications Construction Company (CCCC) Second Highway Engineering was fully completed, marking the world’s longest ultra-high-altitude highway tunnel finally achieved a decisive victory, which will support the development of Tibet’s economic core areas.

Create the World’s Best in the “Forbidden Zone of Life”

The Guigala Tunnel is a control project of the S5 line in Tibet. The starting point and the ending point of the tunnel are respectively located in Xincang Village, Deqing Town, Lhasa Dazi District, Tibet, and Nianguo Village, Sangye Town, Zha Nang County, Shannan, Tibet. The altitudes of the tunnel entrance and exit are 4,248 meters and 4,117 meters respectively, the left and right holes of the tunnel are 12.79 kilometers long and 12.78 kilometers long respectively.

Looking at the world, there are many tunnels that are 4,000 meters above sea level, or have a length of more than 12 kilometers. However, the Guigala Tunnel is currently the only one combining the length and the altitude, being the longest and only ultra-high-altitude highway tunnel in the world.

Achieving this unique and best result also means the realization of countless most severe difficulties in the world. In a plain area, it will take up to four years to open a tunnel of the same length, but in Tibet with more than 4,000 meters above sea level, the difficulty has increased countless times.

The number one challenge facing the project is the difficulty of survival caused by high altitude accompanied by high cold and hypoxia. Statistics show that in areas above 4,000 meters above sea level, more than 60% of people will experience altitude sickness such as headache, dizziness, palpitation, and shortness of breath. In severe cases, emphysema and cerebral edema may even be life-threatening. This is extremely unfavorable to the human body, thereby greatly affecting construction efficiency.

Secondly, the remote location of the project is highly difficult to transport materials, and the tunnel construction is also accompanied by unfavorable geological conditions such as bias pressure, rich water, rockburst, and gas. In addition, the long Guigala tunnel, the steep slope of the inclined shaft, and the long ventilation distance also brought great technical challenges to the construction.

In the face of these worldwide difficulties, the project team adopted the construction mode of “replacing workers with mechanization and reducing workers through AI implementation”, and used a three-arm rock drilling jumbo, wet spray manipulator, bolting jumbo, milling machine, electric loader, electric excavator in targeted tasks. The introduction of advanced equipment effectively reduced manual operations and labor intensity.

Plus, the project team also introduced the BIM management system and other digital solutions to create a “smart construction site”, grasping construction difficulties and construction procedures through visual models. While ensuring safety, the project quality and work efficiency were greatly improved. During the construction process, the project insisted on people-oriented, strengthened occupational health management, set up infirmaries, installed oxygen generators, equipped with mobile oxygen bars, and conducted regular physical examinations for employees to fully protect the health of workers.

To overcome dispersed remote locations and poor geological conditions, the project team actively carried out technical research to reduce over-consumption and loss of materials and effectively reduced the cost of raw materials. Through route inspection and optimization, the project team avoided the geological conditions, such as bias voltage, shallow burial, and unfavorable geology, that do not meet the construction requirements, effectively reducing construction risks and ensuring construction safety and progress.

Furthermore, the project team actively innovated in ventilation, excavation, application of new materials, optimization of inclined shafts, optimization of arch frames, etc. The three-dimensional technical disclosure has effectively promoted the staff’s mastery of the key construction technologies of the project.

It is worth mentioning that despite the difficult project conditions, the construction unit still adhered to the low-carbon concept, promoted electrification and emission reduction, paid attention to the protection of the local ecological environment, tried its best to reduce environmental disturbances, and prevented damage to water sources and mountain vegetation. Green construction.

Make an excellent example for high-altitude projects worldwide

Opening Tibet S5 Line Lhasa-Zedang Expressway Project, including the Guigala Tunnel, is an important strategy to implement the strategy of governing Tibet in the new era and improve people’s livelihood. It is an important part of the 3-hour economic circle and the 3-hour comprehensive transportation circle of the whole zone.

It is expected that after the opening of the S5 line in Tibet at the end of the year, the layout of the regional transportation network will be further improved, and the construction of a new comprehensive transportation network system in Tibet will be promoted, thereby optimizing the urbanization pattern and providing a more convenient and smooth road channel for the development of local resources, which will be of great help to the development of Tibet.

The local people have been looking forward to the completion of the Guigala Tunnel for years. As the tunnel connects Lhasa and Shannan on both sides of the mountains, the journey to cross the mountains from more than three hours will be shortened to more than one hour, successfully connecting people in remote areas of the plateau with the outside world.

The completion of the tunnel will not only be more beneficial for local Tibetans to study and work in different areas, but also help local agricultural products to go out of the mountain villages, creating greater economic benefits, thereby promoting the development of local agriculture and animal husbandry and rural revitalization.

In recent years, with the rapid implementation of the Belt and Road initiative, the demand for transportation infrastructure construction in alpine and high-altitude areas has become increasingly strong.

Effectively overcoming the complexities of high-altitude, severe climate, and geological conditions, and realizing efficient and high-quality promotion of engineering construction are increasingly becoming a worldwide problem that needs to be solved urgently.

The success of the Guigala Tunnel, whether in terms of technological innovation, raw material application, or intelligent control, has provided a useful reference for the smooth and efficient development of such projects.

(Source: cnwest, ifeng, souhu)